Description

Summit 30″ SmartCut Flatbed CNC Lathe, SC30-4

Inventory # 8070

Model: SC30-4

Description:

The SmartCut Flatbed CNC Lathe Series from Summit is rugged and dependable. A combination of manual and CNC operation gives this series unbeatable precision for the finest finishes

SmartCut’s standard Fagor 8055TC controller is self-teaching. You can produce a part manually. Then, with a few simple keystrokes, the controller stores the machining sequences and generates a part program. At a later time, retrieve the program. Enter the number of parts to be produced, and SmartCut does the rest. The control language is conversational or G-code, with on-screen menus and prompts to make programming virtually foolproof

The power of the control features combined with manual hand wheels offers a variety of production applications. It enables you to use a single machine for one-off or prototype production, or set it in a semi-automatic mode for small production lots, and in its fully-automatic mode for medium-length production runs

Specifications:

Swing Over Bed: 30″

Swing Over Slide: 22″

Swing Over Gap: 37″

Hole Through Spindle: 4 1/8″

Spindle Speeds: 22 – 1,500 RPM (Variable)

Spindle Nose: A2-11

X-Axis Feed Rate: 0 – 250 RPM

Z-Axis Feed Rate: 0 – 400 IPM

Tailstock, Quill Diameter: 3″

Tailstock, Quill Travel: 8.8″

Z-Axis Servo: 2.7 HP

X-Axis Servo: 1.4 HP

Spindle Motor: 20 HP

Standard Features:

Available in 40″ – 160″ center distances

Up to 4,400 lbs. part capacity

Heavily ribbed cast bed and base

Hardened and precision-ground bed ways

Precision ground ball screws

Infinitely variable speed ranges

Yaskawa spindle drive

Constant surface speed

Fine feed electronic hand wheels

Inch-metric capabilities

T-slotted cross slide for multiple accessory compatibility

Control Features:

Fagor 8055 CNC Control

Conversational or G Code Programming

Communications via USB and Ethernet

Versatility: It is a DRO when working manually; it is a motion controller when performing semi-automatic operation; it is a full-powered CNC control for automatic operation

Thread Repair Cycle

Standard Equipment:

Steady Rest with Roller Tips

Follow Rest

Coolant System

Work Light

Sliding Enclosure Doors

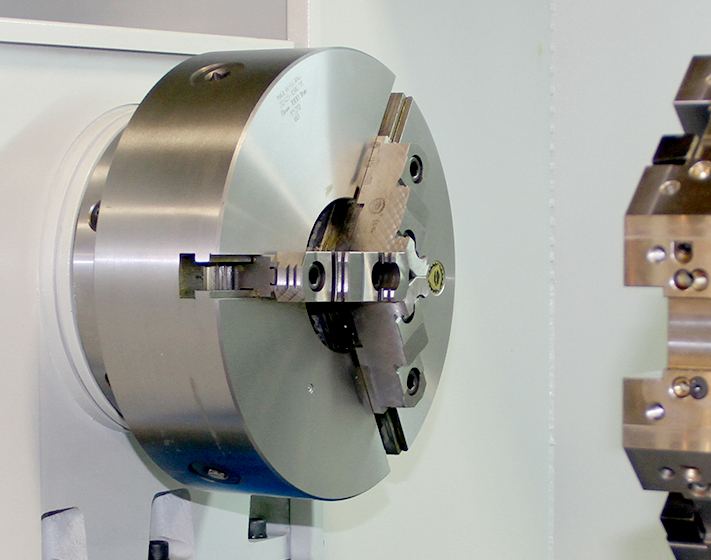

3-Jaw Chuck

FOB Factory – Contact us for pricing and availability