Description

Haco 33 Ton 6-Axis Programmable CNC Turret Punch Press

Inventory # 7412

Model: Q3

Specifications:

Punch Capacity: 33 Tons

Max. Sheet Thickness: 0.256″

Max. Sheet Weight: 440 lbs.

Maximum Hit Rate of Punching Head: 1200 h/min

Stroke X-Axis: 80″ , 3150 ipm , 590 i/s²

Stroke Y-Axis: 60,4″ , 3150 ipm , 393 i/s²

Speed of C-Axis 30° , 60° , 90°: 86 ms , 108 ms , 122 ms

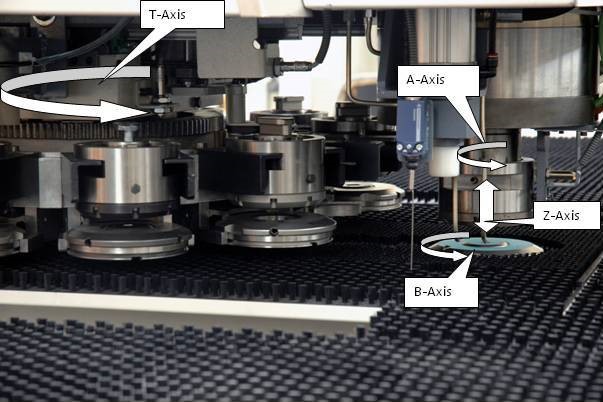

Stroke Z-Axis (Max. Punching Stroke): 1 7/16″

Max. Power Consumption: 25 kW (50 HZ) , 32 kW (60HZ)

Average Power Consumption: 8 kW (50 HZ) , 11 kW (60HZ)

Voltage: 220 v / 480 v / 3 ph

Standard Features:

Heavy-Duty Frame – Total Weight 12.000 Kg

Problem-free continuous punching-capacity of 30 Tons, max. 6.5mm sheet thickness

Fully stress-relieved frame by means of heat treatment (up to 600 degrees Celsius, 5 days cooling off cycle)

High geometrical machining accuracy (up to 0.01mm)

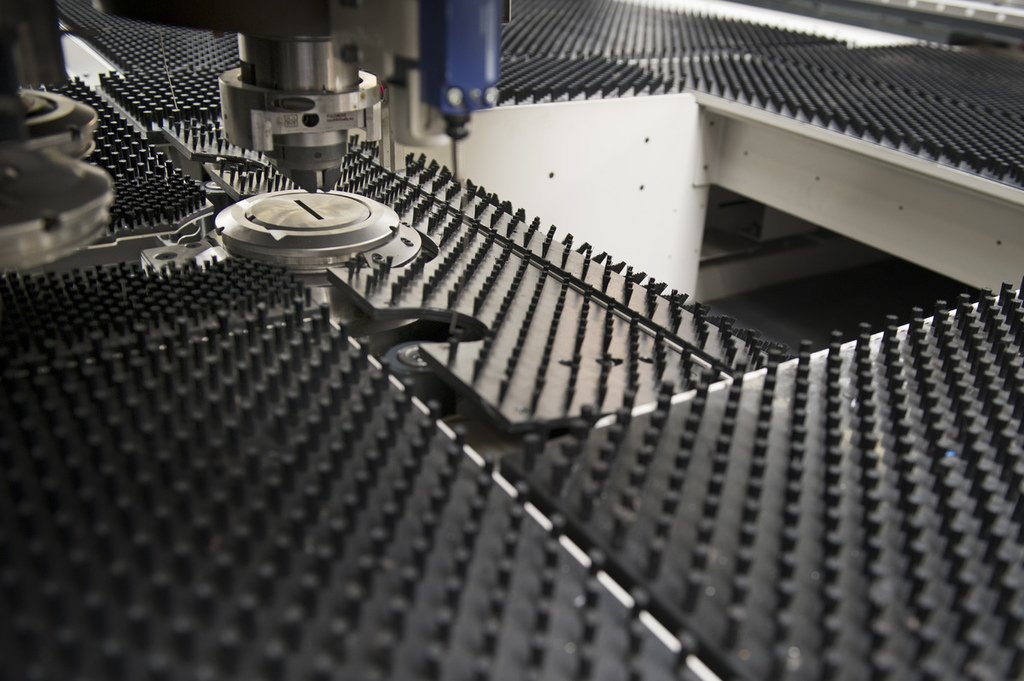

Low Maintenance Punching head situated outside of the turret – no turret-wear

Programmable punching depth for optimum cutting quality and minimal tool-wear – no ‘shimming’ after grinding the punching tools.

All tool-stations indexable at high indexing speed (250 Rev/min)

Positive clamping – hydraulic quick-clamping of tool holders

Fast and accurate loading of the tools in the turret

Simple construction of the tool holders

User-friendly Windows ® based CNC Graphics control

Heavy AC servo motors for X- and Y-axes

Standard executed with:

· Hydraulic fast speed punching head

· Automatic oil-mist lubrication of the tools

· Programmable repositioning in X-direction

· Scrap-removal

· 4 vibration dampers

· Part chute

Equipment Included:

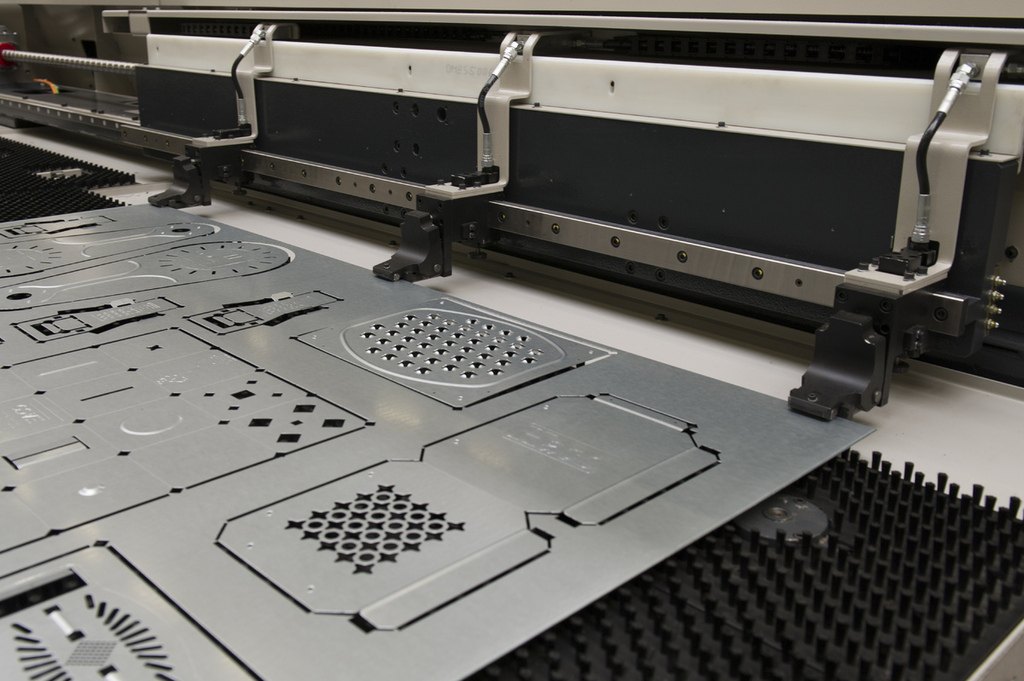

Stationary Brush Table on Both Sides: 100″ x 40″

Standard Part Chute

Tool-turret of 20 stations

20 complete tool holders adapted for Trumpf style punches and dies, (punches and dies not included) and with blank HACO style stripper plates

6-Axes Programmable CNC control (X-Y-Z-T-C1-C2)

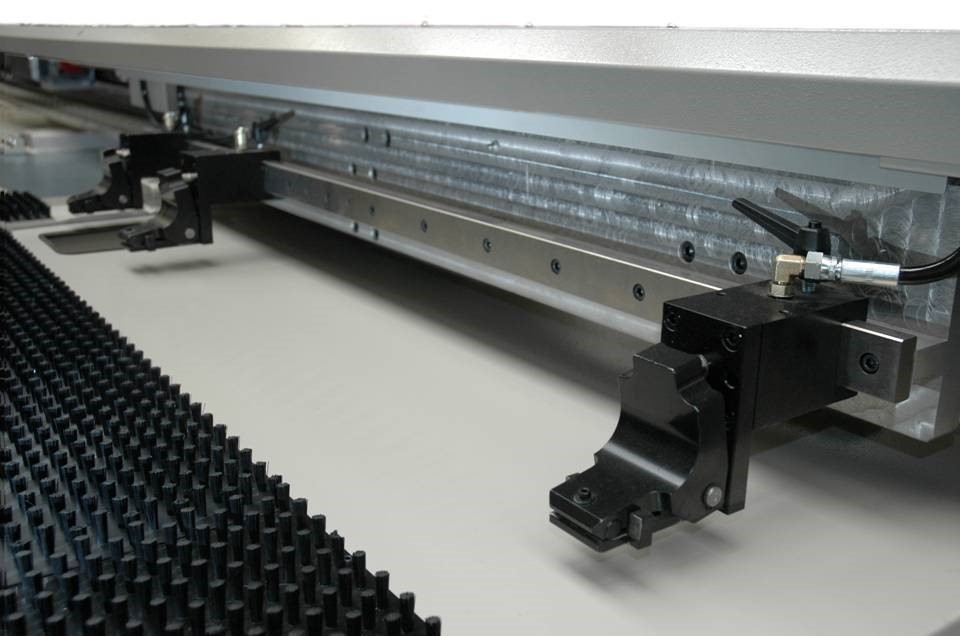

(4) Repositioning cylinders (2 upper and 2 lower cylinders)

(3) Hydraulic sheet-clamps

CE light guard

Quick Tool Set Device

(4) Vibration dampers

Workpiece chute

Scrap container

Vacuum system for slugs

Maintenance and programming manuals

HacoSoft Punch CAD/CAM Software:

· Can be used to prepare the whole punching production and generate the CNC programs for the Haco CNC punching machines

· Windows based software

· User friendly 2D CAD functions

· Importing of 2D files : dxf, me10, hpgl, dwg

· Graphical tool library for normal and special tools

· Manual and automatic tool assignment

· Rectangular and true shape nesting

· Manual, automatic and combined nesting

· Common cuts, micro-joints

· Manual and automatic repositioning

· Graphical simulation of the punch process

· Fully integrated in the HacoSoft CAD-CAM System

· Tele service via internet

· Programmable tool functions

· Programmable part chute

· Nest report with time calculation

· Tool linking ( punch, form, tapping)

· Manual and automatic punch sequence

· Adaptive stroke

Mechanical Specifications:

Overall Dimensions: 210″ L x 161″ W x 90″ H

Overall Weight: approx. 26,448 lbs.

Price on Request

FOB Factory