Description

Haco 10′ x 165 Ton Multi-Axis Hydraulic CNC Press Brake, ERM 165 10 8

Inventory # 7423

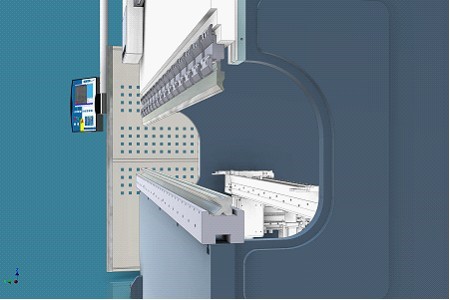

Model: EuroMaster ERM 165 10 8

Specifications:

Working Length: 120″

Capacity: 165 Tons

Distance Between Housings: 102″

Gap: 15 3/4″

Daylight Opening: 20.47″

Stroke: 10.6″

Table Height: 36″

Fast Approach Speed: 472″ /Min.

Max. Working Speed: 23.6″ /Min.

Fast Return Speed: 295″ /Min.

Motor: 20 HP

Standard Features:

All steel welded interlocked construction.

Beam driven by a motor-pump group and two push down hydraulic cylinders

Electro-hydraulic levelling and depth stop setting from the beam by SYNCHRO system

Automatic compensation of the side frame deflection by means of table reference measuring scales, giving feedback to the SYNCHRO system

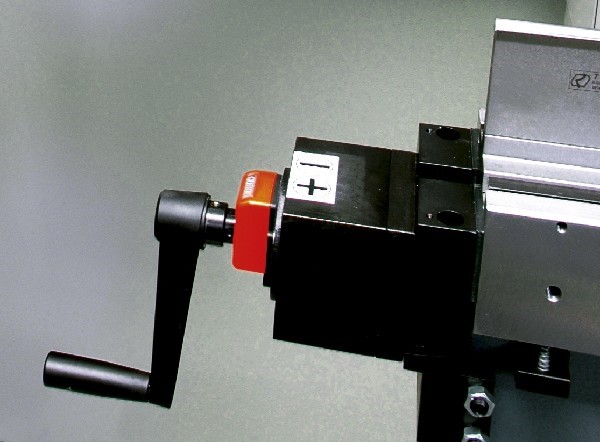

Fast and user friendly manual displacement from the front.

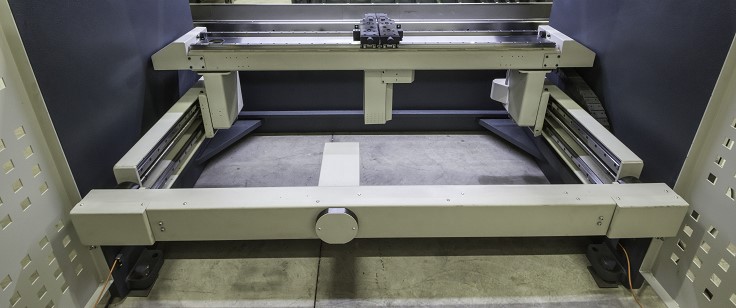

2-Axes backgauge with ball screws and linear guideways

Quick manual clamping system tooling

Manual crowning for system tooling

FastBEND-2D MT Premium Control:

The FastBEND-2D MT Premium 21.5″ control is suitable for generating and executing 2D and 2.5D workpieces

3D workpieces that are generated externally (offline) can be visualized and executed

The FastBEND-2D MT Premium 21.5″ control is equipped with an industrial Multi Touch Screen from Beckhoff®

Multi-Touch Technology with tablet features

Intuitive Interface with a minimum number of interactions to draw the workpiece (by Point to Point method or Smart Draft) and generate the corresponding program

Combined ‘numerical-graphical’ user interface

Smart Draft: Innovative drawing method for generating 2D workpieces

Multi-Tasking: Workpiece drawing with instantaneous collision detection and calculation of the bending sequence in the background (real-time solutions)

Step Previewer: Bar with possibility of horizontally scrolling of the bending steps, visualizes all steps in the development and production mode of a program

Combined Icons: Multiple functionalities by means of one single icon

Simulation Mode: Simulation run from the bending sequence before execution of the bending program

Equipment Included:

40″ X-R Backgauge

CNC Crowning

European Standard Quick Tool Holders (American Standard Optional)

(2) 29″ Movable Sheet Supports, 1 T-Slot and 1-Tilting Stop

Mechanical Specifications:

Dimensions: 167″ x 67″ x 115″ H

Weight: approx. 21,385 lbs.

Contact us for special pricing and availability

FOB Factory