Description

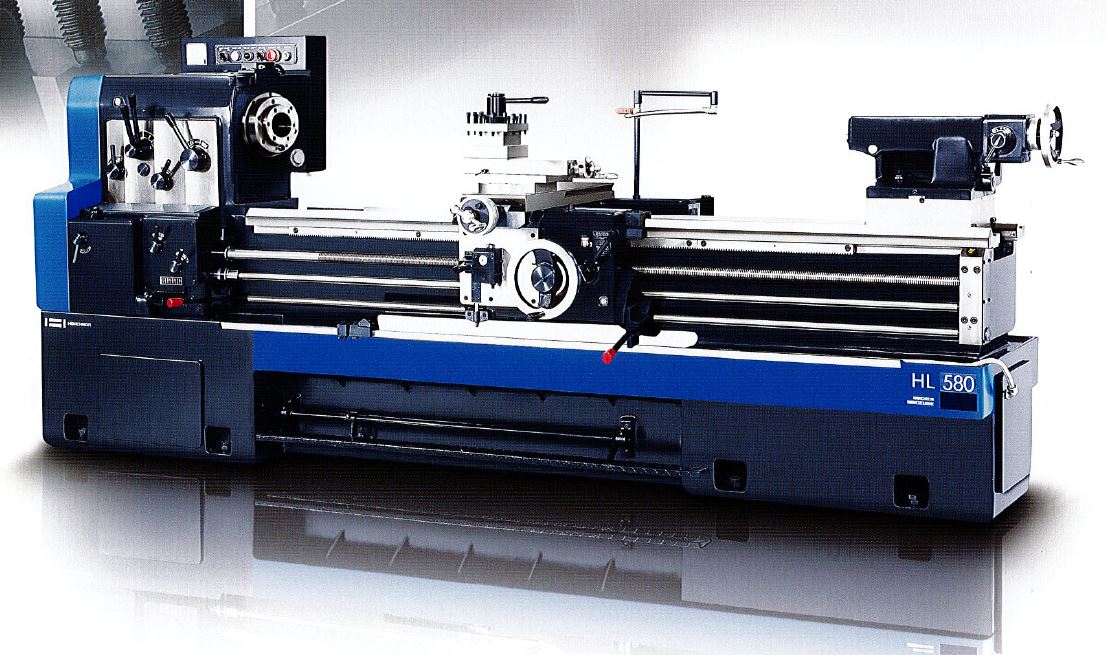

Whacheon 23″ x 59″ Lathe, HL-580

Inventory # 3889

Model: HL-580-1500

Made in Korea to Japanese Standards

Specifications:

Capacity:

Swing Over Bed: 22.83″

Swing Over Cross Slide: 14.17″

Swing Over Gap: 31.88″

Distance Between Centers: 59.05″

Spindle:

Spindle Nose: A1-8″ or D1-8″

Spindle Bore: 3.03″

Taper of Spindle Bore: M.T. #7

Taper of Center: M.T. #5

Number of Spindle Speeds: 12

Range of Spindle Speeds: 28 – 1,350 RPM

Carriage:

Number of Feed Changes: 40 Steps

Longitudinal Feed (Z-Axis): 0.0014″ ~ 0.0228″ /Rev.

Cross Feed (X-Axis): 0.0014″ ~ 0.0228″ /Rev.

Cross Slide Travel: 11.81″

Compound Rest Travel: 6.69″

Bite Holder Size: 1 1/4″ x 1 1/4″

Threads:

Lead Screw: 1.49″ x 0.23″

Inch Threads: 112 ~ 2 TPI

Metric Threads: 0.0098″ ~ 0.55″

D.P. Threads: 8 ~ 112

Module Threads: 0.25 ~ 3.5

Tail Stock:

Spindle Travel: 5.90″

Taper of Center: M.T. #5

Bed:

Width: 16.53″

Length: 106.49″

Motors:

Coolant Pump: 0.13 HP

Main Motor: 10.05 HP

Standard Features:

Number (12 steps) and range of speeds of this lathe is created so that the most suitable cutting speed may be given to any size of workpiece diameter within the possible range of cutting size, namely, within the range of swing over bed

The main spindle is supported at three points by precision bearings and its hole is generously sized

Automatic forced lubrication system supplies lubricant to every sliding way and driving mechanism inside the headstock

By lubricating device installed inside apron, automatic lubrication is provided between carriage slide ways and bedways

The feed mechanism permits positive shift from the normal feeds to the reverse, and vice versa, by simple operation of the lever on the front face of headstock housing or also the one at the apron

An adjustable carriage feed stop dog is provided on bed as well as a positive micrometer stop

The machine is equipped with an overload safety device for feeding and thread cutting

Optional Taper-cutting attachment and rear tool-post are easily attached by means of carriage grooves of both sides

Cross feed screws always supply a proper quantity of grease more than one time per a week for maintaining smooth travel under maximum accuracy

Bed is designed to prevent torsion, side-wall is double wall and rib type

Hardened and ground bedways are made of high tensile cast iron. Produced under the license of UK Meehanite Know-How

Lower portions of bed casting are box-shaped and are full length, forming the legs, chip pan and coolant reservoir

The hydraulic disk brake provides safe quick braking of the spindle without generation of heat in the headstock

Diameter of tailstock shaft is 75mm and the overall length is hardened and ground. By loosening clamp lever, which keeps higher sliding efficiencies and better wear resistance of carriage

Standard Equipment:

Motor

Coolant Equipment

Driving Plate (11 3/4″)

Center Sleeve M.T. # 7

Live Center

Dead Center (Cemented Carbide Tip) M.T. # 5

Face Plate (Gap Type Only) (17 3/4″)

Steady Rest, 1 1/2″ – 6″

Carriage Micro Stopper

Thermal Relay

Change Gear 60T

Worm Gears (Metric System Only)

Installation Block

Tool Box

Grease Pump

Oil Gun

Box Handle

Hexagon Handle

Spanners

Screw Driver

Parts List and Manual

Mechanical Specifications:

Dimensions: 125.59″ x 45″ x 56.29″ H

Weight: approx. 6,460 lbs.

Contact us for special pricing and availability

FOB Factory