Description

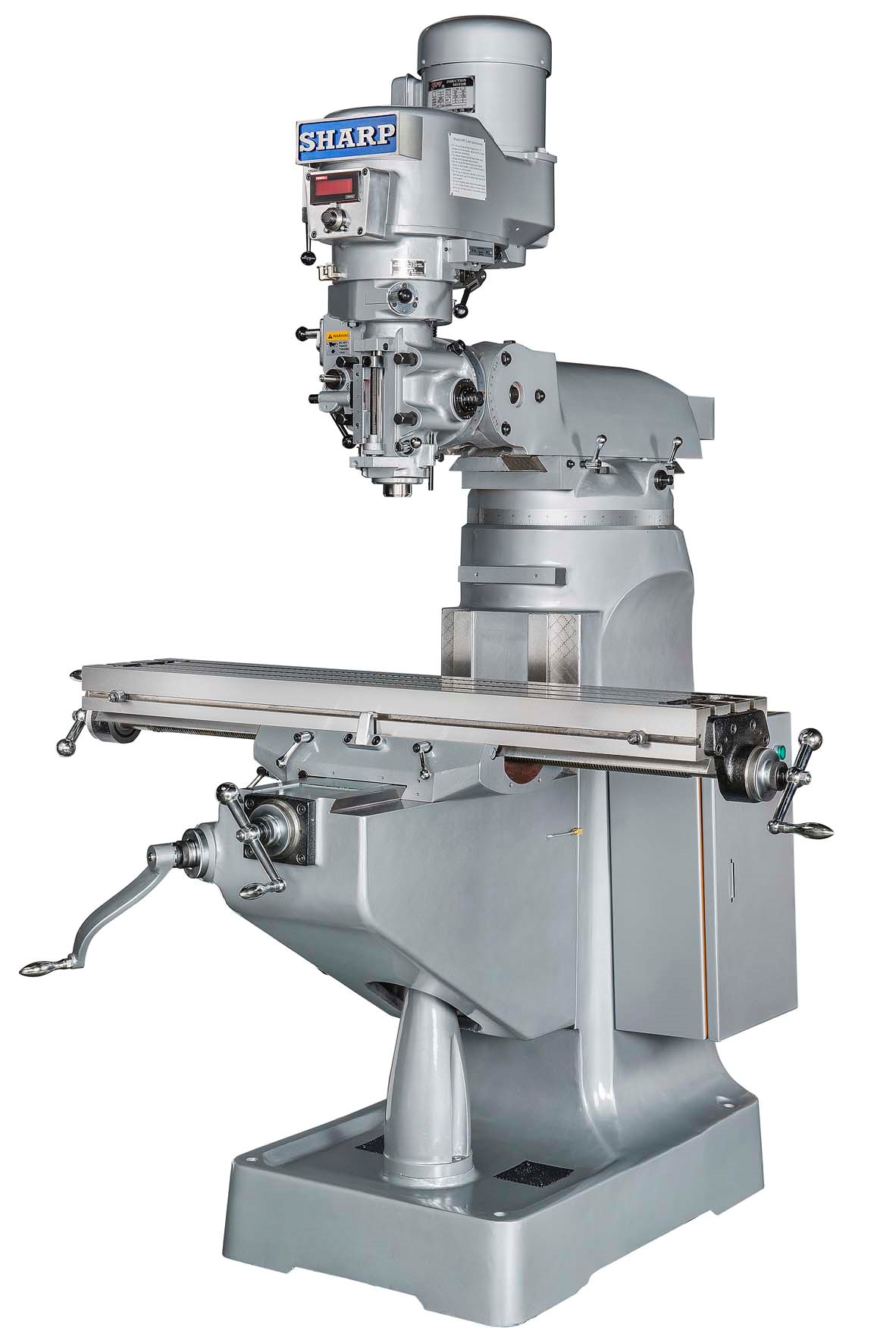

Sharp 9″ x 49″ Vertical Milling Machine with Standard DVS Head, LMV-49-DVS

Inventory # 2534

Model: LMV-49 with DVS Head

Specifications:

Working Surface: 9″ x 49″

T-Slots, Number x Size: 3 x 5/8″

Capacity:

Travels (X, Y, and Z): 36.6″ x 12″ x 5″

Ram Travel: 12″

Knee Travel: 16″

Spindle To Column: 6 3/4″ – 18 1/2″

Spindle Nose to Table: 2 1/8″ – 18″

Spindle:

Nose Taper: R8

Digital Variable Speed Drive (DVS): 65 – 4,500 RPM

Quill Feed, 3-Speed (IPR): 0.0015″, 0.003″, 0.006″

Head Swivels: 360°

Head Tilt, Left to Right: 45°

Head Tilt, Up and Down: 45°

Motor: 3 HP / 220v, 440v / 3ph (220v, Single Phase is Available)

Standard Features:

Hard-Chrome Ways and Gibbs

Precision Ground and Flaked Table

Unique Double Nut Backlash System

Cutler Hammer On/Off Switch

Front and Rear Way Covers

One Shot Lube System (X, Y, Z Axes)

Tool Kit (Includes: Machine Manual, Half Nut Wrench, Wrench 17M, 19M, Set of 6 Allen Wrenches, Philip Screw Driver, Flat Head Screwdriver, Oil Can, Grease Gun, Rear Way Cover Bracket, Pin for Indicator, Can of Paint)

Standard Features:

Digital Variable Speed Drive

R-8 Spindle

Meehanite Casting

Chromed Ways

Self-Lubricating Motor Shaft Extends Pulley Life

ABEC-7 Super Precision Spindle Bearings

Mechanical Specifications:

Dimensions: 84″ x 78″ x 81″ H

Weight: approx. 2,100 lbs.

Contact us for special pricing and availability

FOB Factory