Description

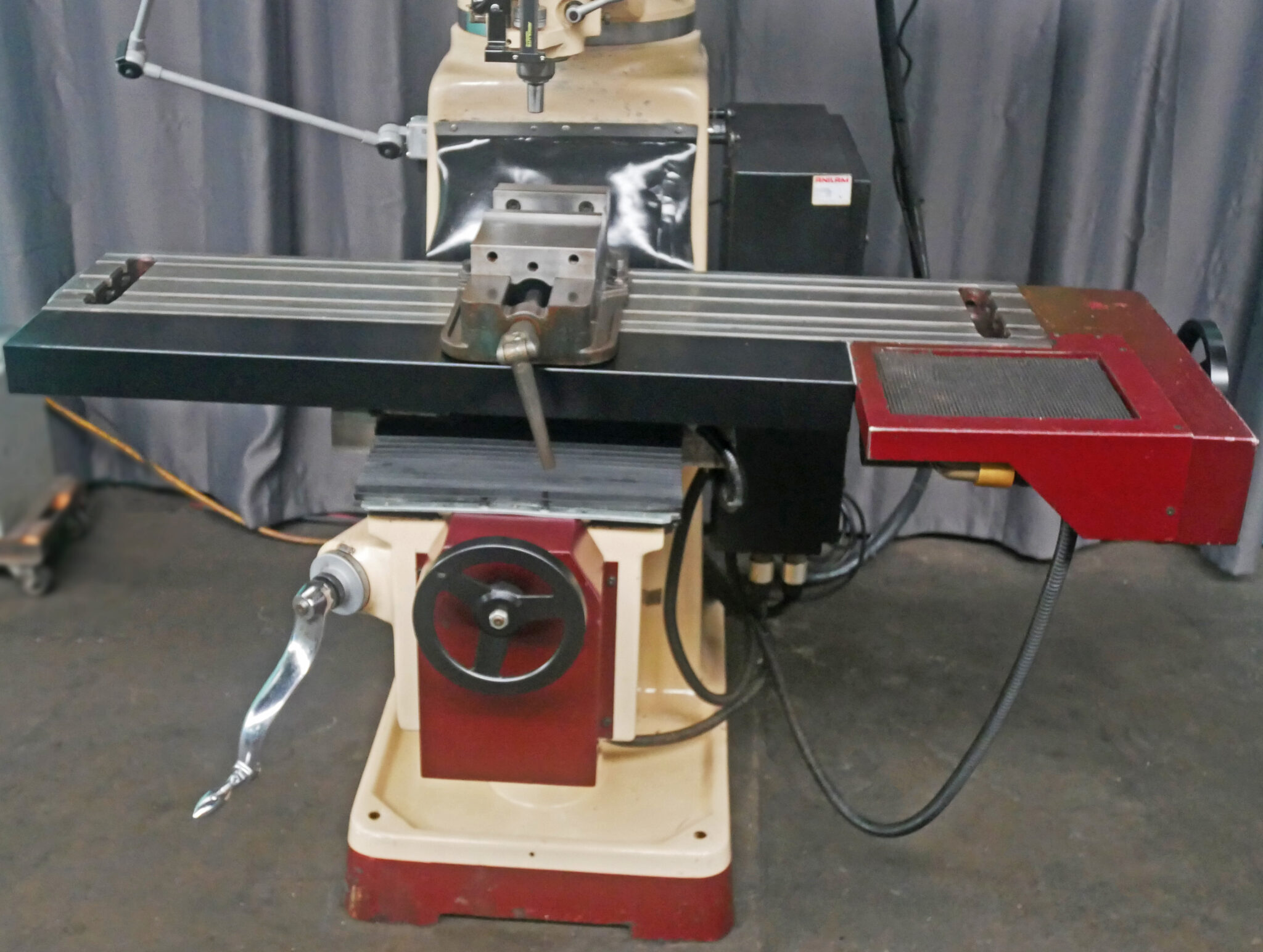

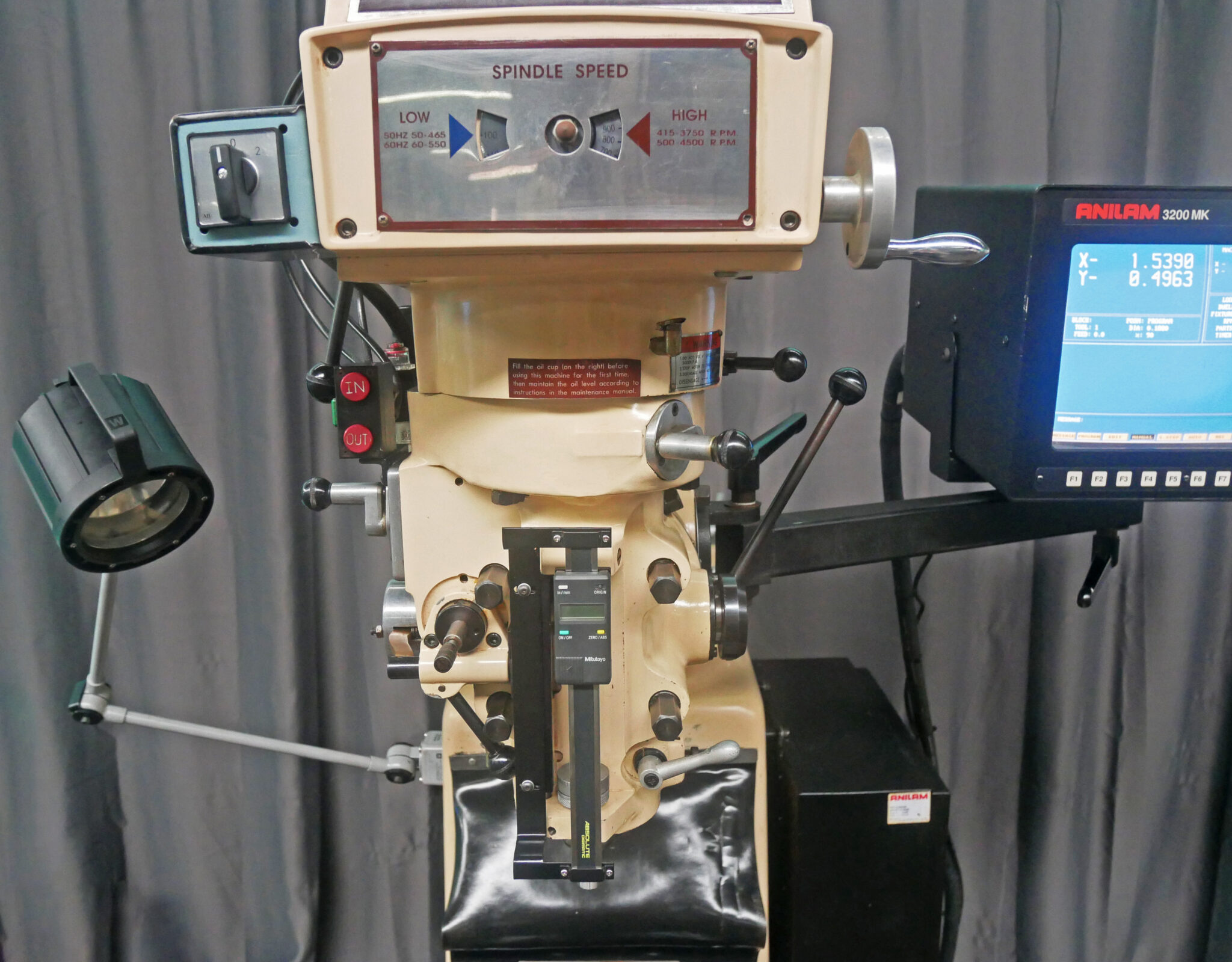

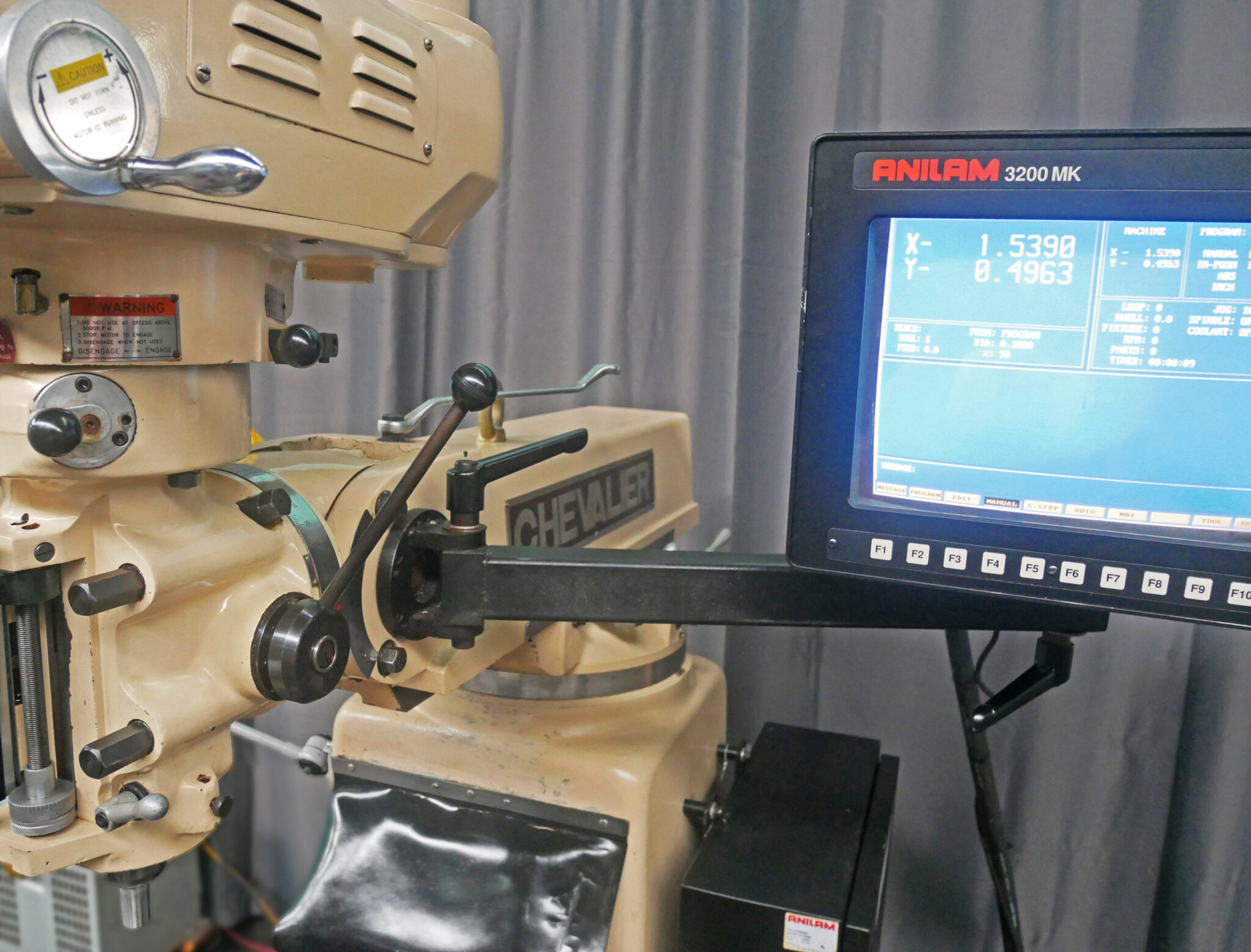

Chevalier 10″ x 50″ Vertical Turret CNC Milling Machine with Anilam 3200 MK 2-Axis Control, Falcon 3A2K

Inventory # 9928-P

Model: Falcon 3A2K

S/N: KC865201

Specifications:

Table:

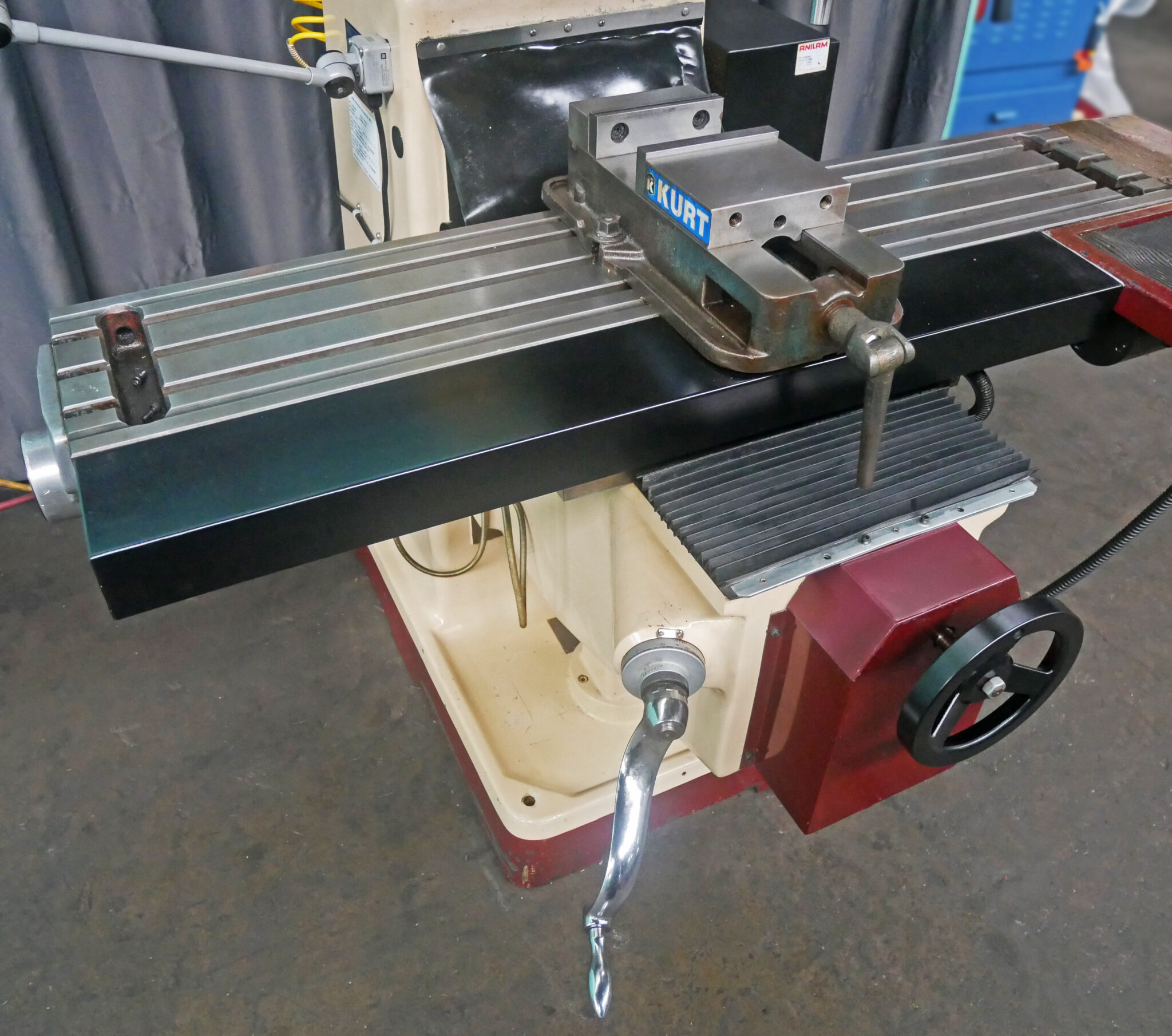

Overall Dimensions: 10″ x 50″

T-Slots (3): 2 1/2″

T-Slot Size: 16mm

Work Load Capacity: 900 lbs.

Travel:

Longitudinal Travel: 31″

Cross Travel: 14″

Knee Travel: 15 3/4″

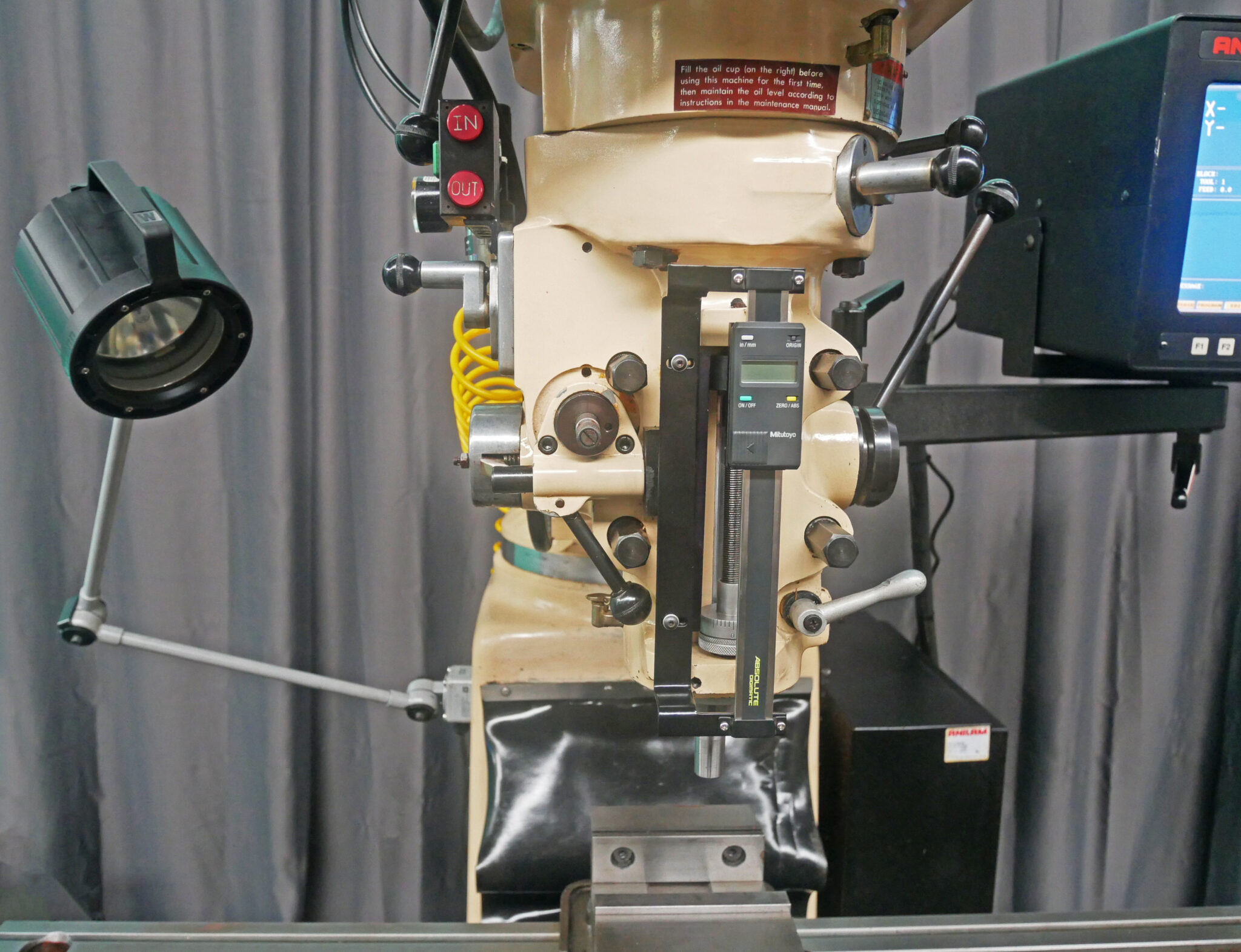

Quill Travel: 5″

Ram Travel: 24″

Head:

Head Swivel (Left/Right): Rigid

Head Tilt (Front/Back): Rigid

Overarm Swivel: +/- 45°

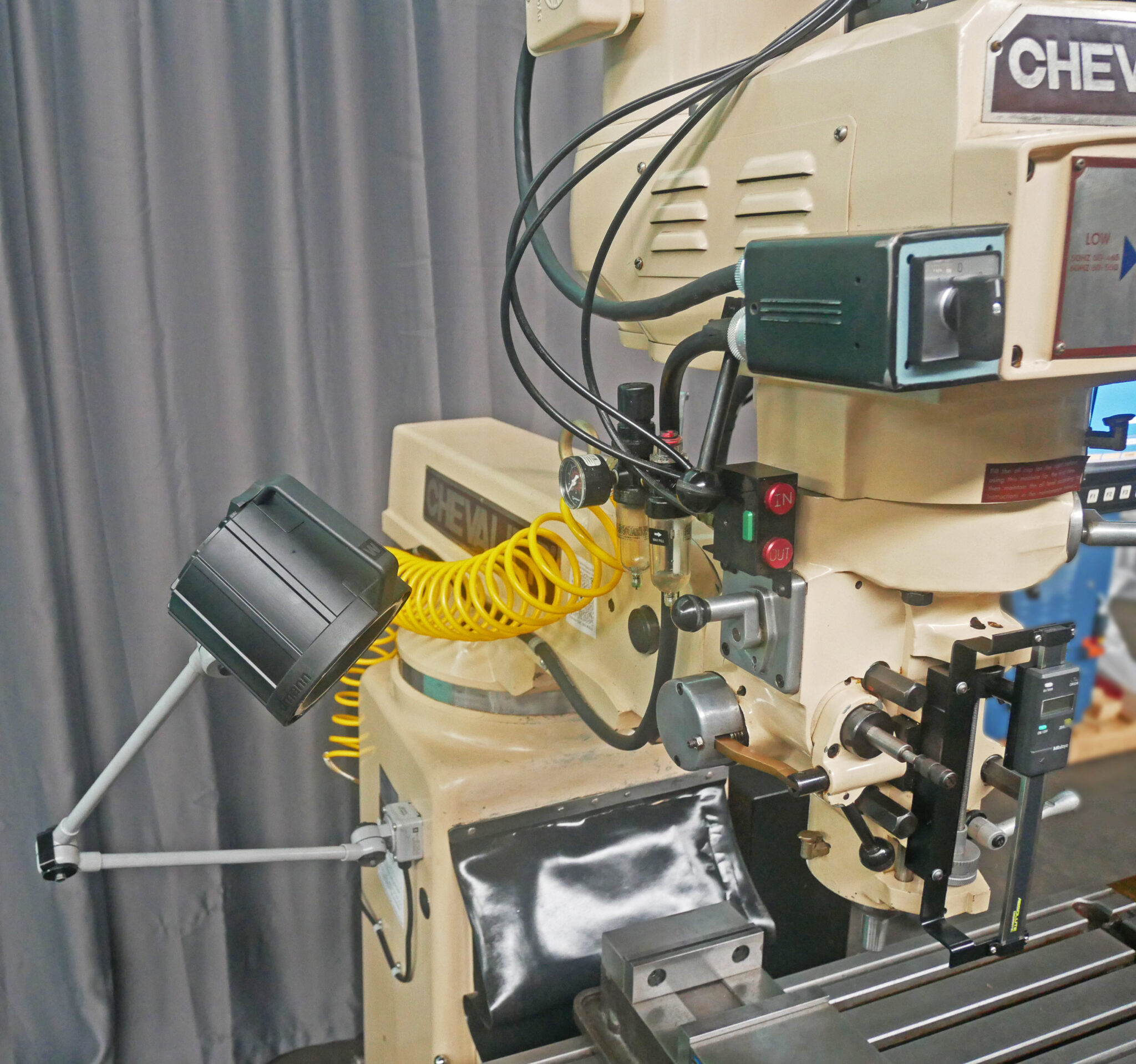

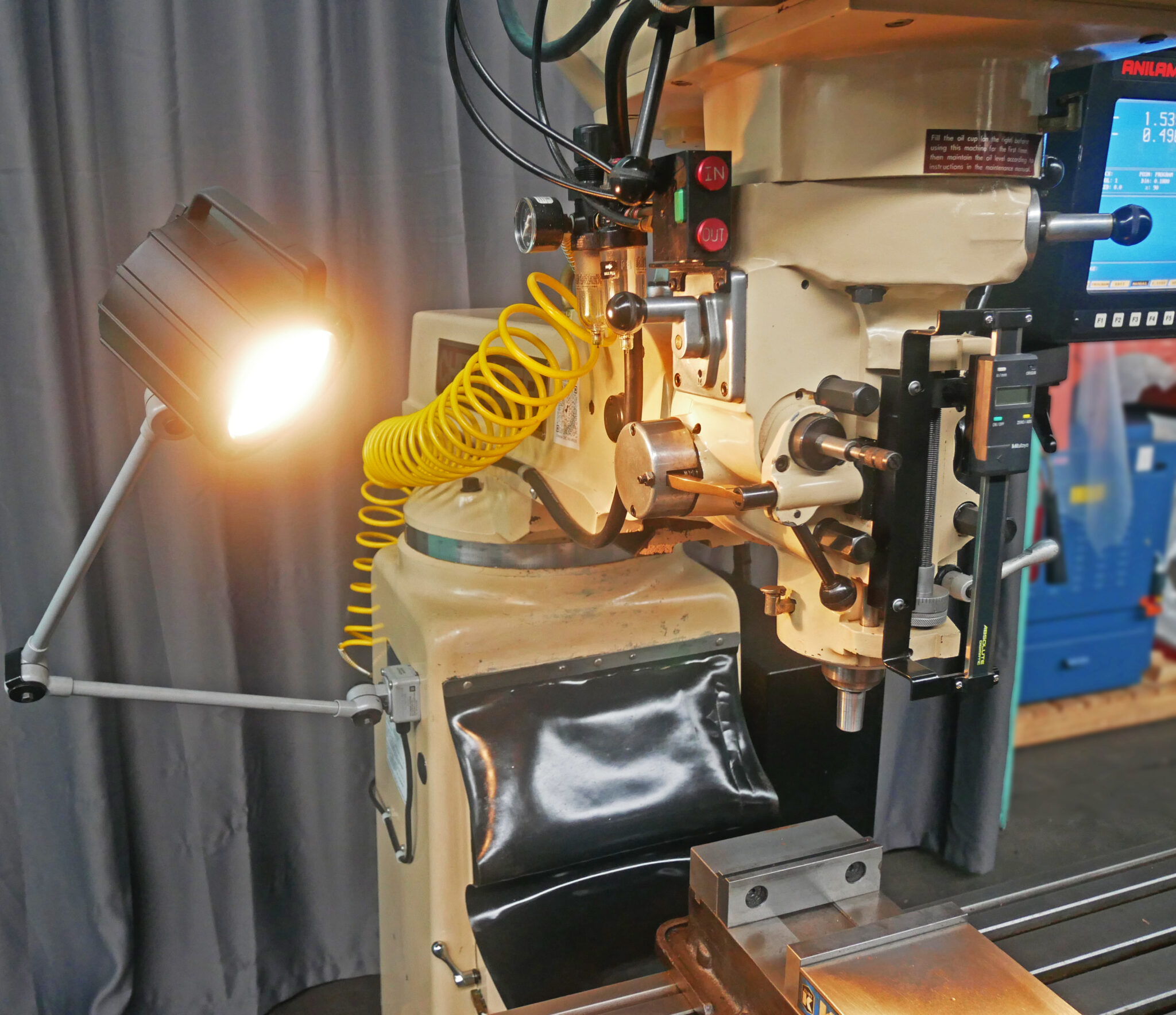

Spindle:

Nose Taper: R-8

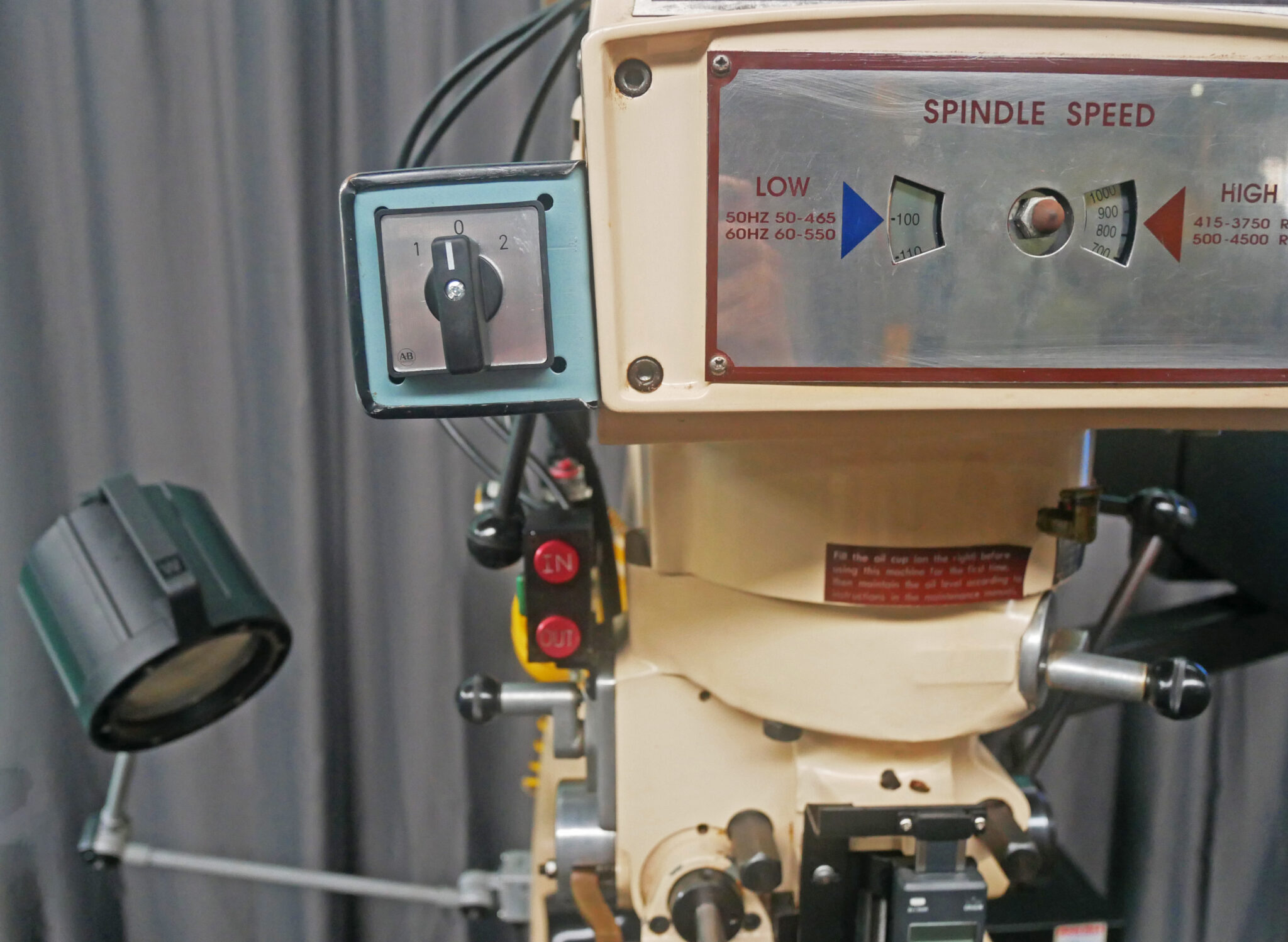

Spindle Speeds: 60 – 4,500 RPM

Spindle Center to Column: Min. 4″ – 18 3/4″ Max.

Spindle Nose to Table: 18 1/2″

Quill Feed Rates (2-Axis): 0.0015″, 0.006″

Performance:

Traverse Rate (X, Y, & Z-Axis): 200 IPM

Feed Rates (X, Y, & Z-Axis): .1 – 120 IPM

Positioning Accuracy: +/- .0005″

Positioning Repeatability: +/- .0002″

Resolution (Closed Loop Optical Encoder): .0001″

Power and Air Requirements:

Air (for Power Drawbar): 80 PSI, 3-5 CFM

Control Electrics: 110v / 1ph

Spindle Motor: 3 HP / 220v, 440v / 3ph

Standard Features:

+/-.0002″ Repeatability, +/- .0005″ Accuracy

Anilam 3200/3300 MK Control with Easy-to-Use Conversational Programming

Anilam 3200 Control Features:

MDI Teach Mode

Easy-to-Use Machinist’s Programming Language

Draw While Cutting Graphics and Simulation Graphics

RS232 Communications, Format Floppy Disk

3 1/2″ 1.44 MB Floppy Disk Drive

1.6 GB Hard Drive

Machine Error Compensation

Rotate, Mirror Image, Scaling, Sub-Programs, Repeat Loops

Dwell Function

Absolute and Incremental Programming

Tool Table with Diameter and Length Offsets

1.6 GB Part Program Storage Memory

Fully Upgradable from 2 Axis to 3 Axis

Cartesian/Polar Coordinate Programming and Automatic Corner Rounding

2-Axis Simultaneous Contouring, Canned Cycles, Sub-Routines, Repeat Cycles, Part Rotation, Scaling, Mirror Imaging, and Cavity Mill

Easy-to-Use, Built-in Calculators

1.6 GB Part Program Storage Memory

Leadscrew Pitch Error Compensation

CAD/CAM Systems Compatible

Tool Calibration Offsets

Precision Class 7 Spindle Bearings

Spindle Bore Runout is Consistent within 0.00015″

Rigid, honeycombed ribbed, Meehanite casting

Auto-lube system

Standard Equipment Included:

X and Y Axis Safety Handles

Rubber Chip Covers (Front and Rear)

Control Programming Manual

Optional Equipment Included:

Kurt 6″ D-675 Milling Vise

Kurt Automatic Power Drawbar, R8

Halogen Machine Lamp with Transformer

Mitutoya Quill Scale, Added New

Remote Handwheel

Mechanical Specifications:

Floor Area (Doors Closed): 104″ x 92″

Floor Area (Doors Opened): 104″ x 108″

Height (without Power Drawbar): 84″

Weight: approx. 3,400 lbs.

FOB Our Baltimore, MD Warehouse