Description

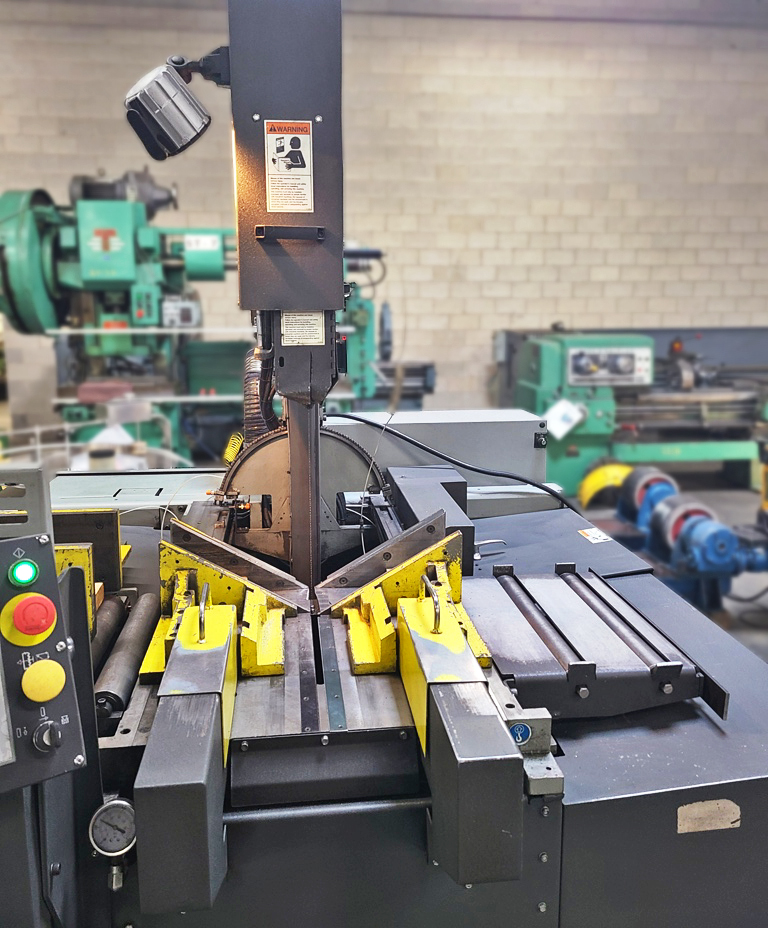

Marvel 15″ Automatic Vertical Band Saw, E380-PC3-60

Inventory # 10055-C

Model: E380-PC3-60

S/N: E-380-0427PC3 “2019”

Specifications:

Round – Head in Straight Position:

@ 0°: 15″ Diameter

@ 45°: 14″ Positive / 13 1/4″ Negative

@ 60°: 9 1/4″ Positive / 8″ Negative

Round – Head in 3° Cant Position:

@ 0°: 14 1/2″ Diameter

@ 45°: 13 1/2″ Positive / 12 3/4″ Negative

@ 60°: 8 3/4″ Positive / 7 3/4″ Negative

Rectangle – Head in 3° Cant:

@ 0°: 14 1/2″ x 20″

@ 45°: 14 1/2″ x 13 1/2″ Positive / 14 1/2″ x 12 3/4″ Negative

@ 60°: 14 1/2″ x 8 3/4″ Positive / 14 1/2″ x 7 3/4″ Negative

Table Load Capacity: 1,000 lbs.

Max. Vise Opening: 15 1/4″

Blade Speed: 60 – 400 FPM, Infinitely Variable

Blade Size: 192″ x 1 1/4″ x .042″

Feed Force: 0 – 300 lbs.

Band Wheel: 16″ Diameter

Motor: 5 HP / 440v / 3ph

Standard Features & Equipment Included:

Automatic Bar Feed: The automatic bar feed design features a 48″ stroke length with indexing speeds of up to 70′ /minute and creep speeds of 33″ /minute. The bar feed vise is electrically driven and combines precision double ball screws with preloaded re-circulating ball linear guides, resulting in positioning accuracy of +/- .005″ per index. The vise itself is hydraulically clamped to prevent material slippage. Material can also be fed through the machine manually in both directions using the shuttle vise

0° – 3° Canted Column: Adjustable 0° or 3° forward approach angle, for notching, or increased efficiency in cutting of structural materials. Must specify if 0° or straight column set up is desired as the machines are by default shipped from the factory in 3° canted column

Feed Pressure: Direct force sensing electric ball screw feed which combines more consistent feed force with greater control, 0 – 300 lbs. column travels on re-circulating linear ball ways. Feed pressure can be automatically set when material is selected

Vises: Hydraulic, half stroking with 6.7″ high x 11.4″ wide 60° faceplates

Jammed Blade Protection: Automatically senses resistance as the column returns and stops to prevent blade damage

Upper Blade Guide Arm: Hydraulically positioned and locking, travels on linear guides, controlled through PC3 touch screen control

Control: Provides a Programmable Logic Control unit with a 9″ color, touch screen display. The control features graphical part programming with memory for up to 500 jobs and parts, as well as a material selection chart and customizable material library. Both blade speed and feed force are automatically set according to material type for optimal cutting performance. Job features include inch/metric capability, out-of-stock shut down device, a fast cut job option, and expanded memory storage using removable media. Also includes Jammed Blade Protection that senses resistance as the column returns and stops to prevent blade damage

Mechanical Specifications:

Dimensions: 137″ x 88″ x 92″ H

FOB York, PA Warehouse 17402