Description

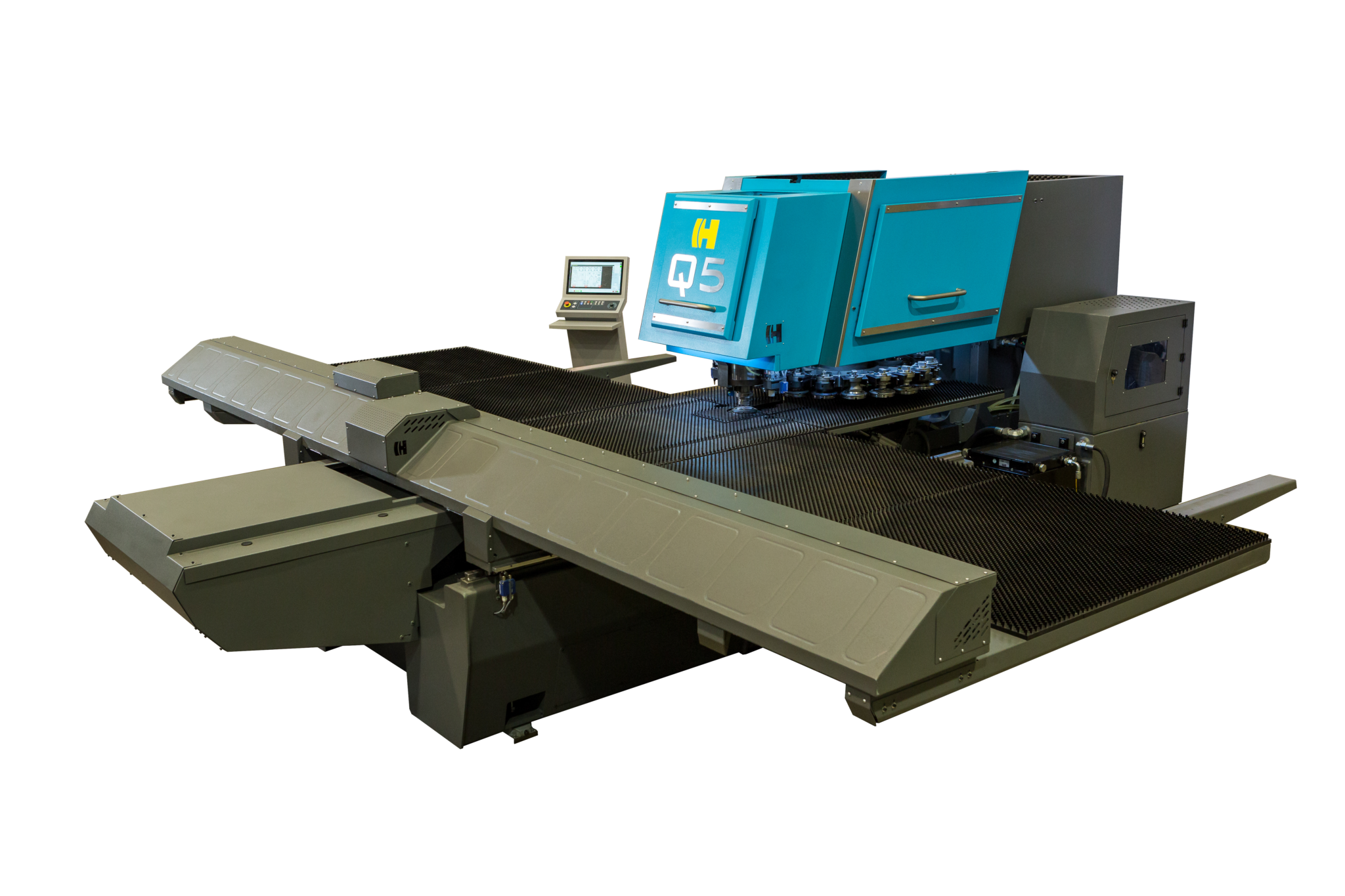

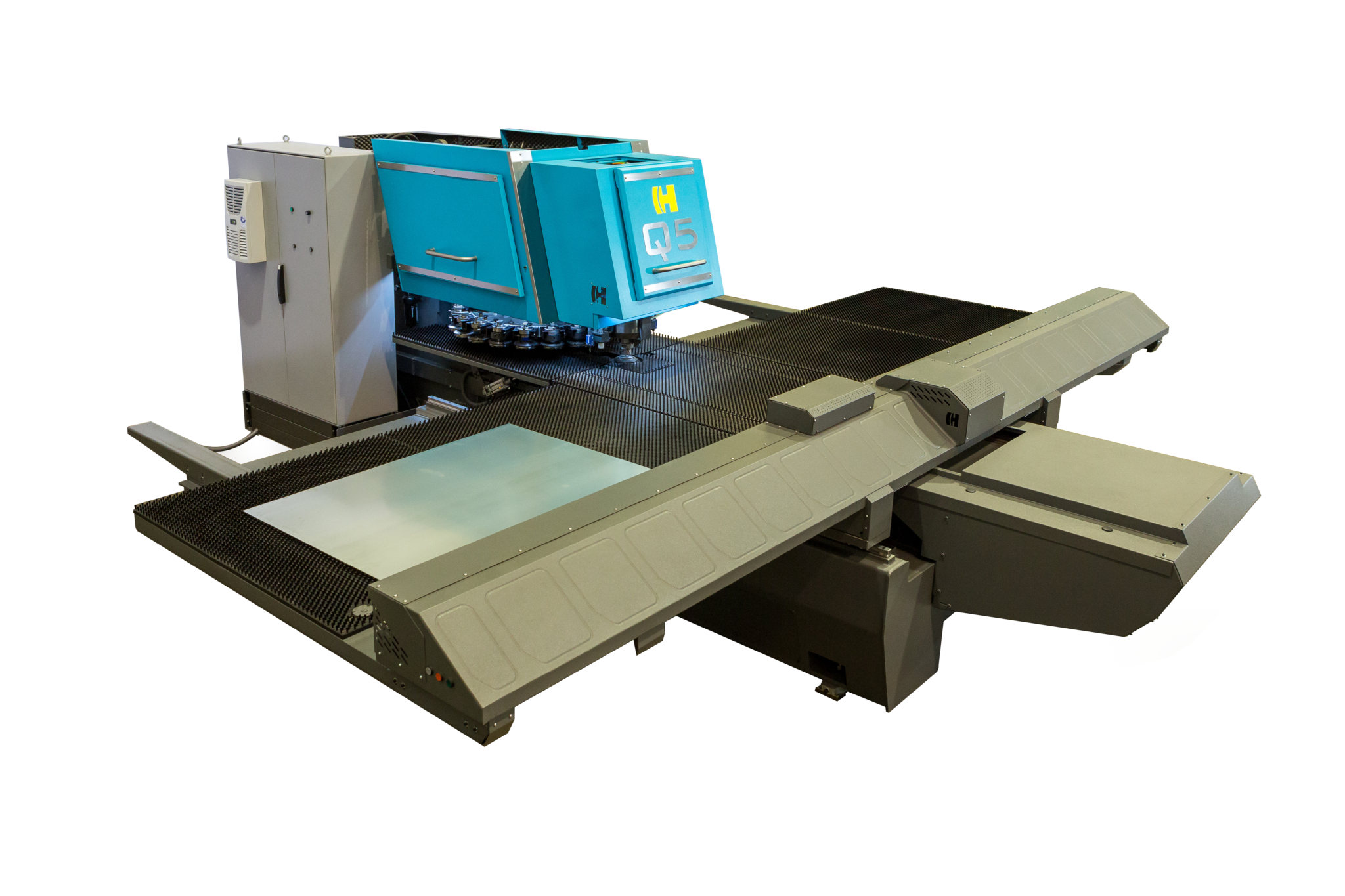

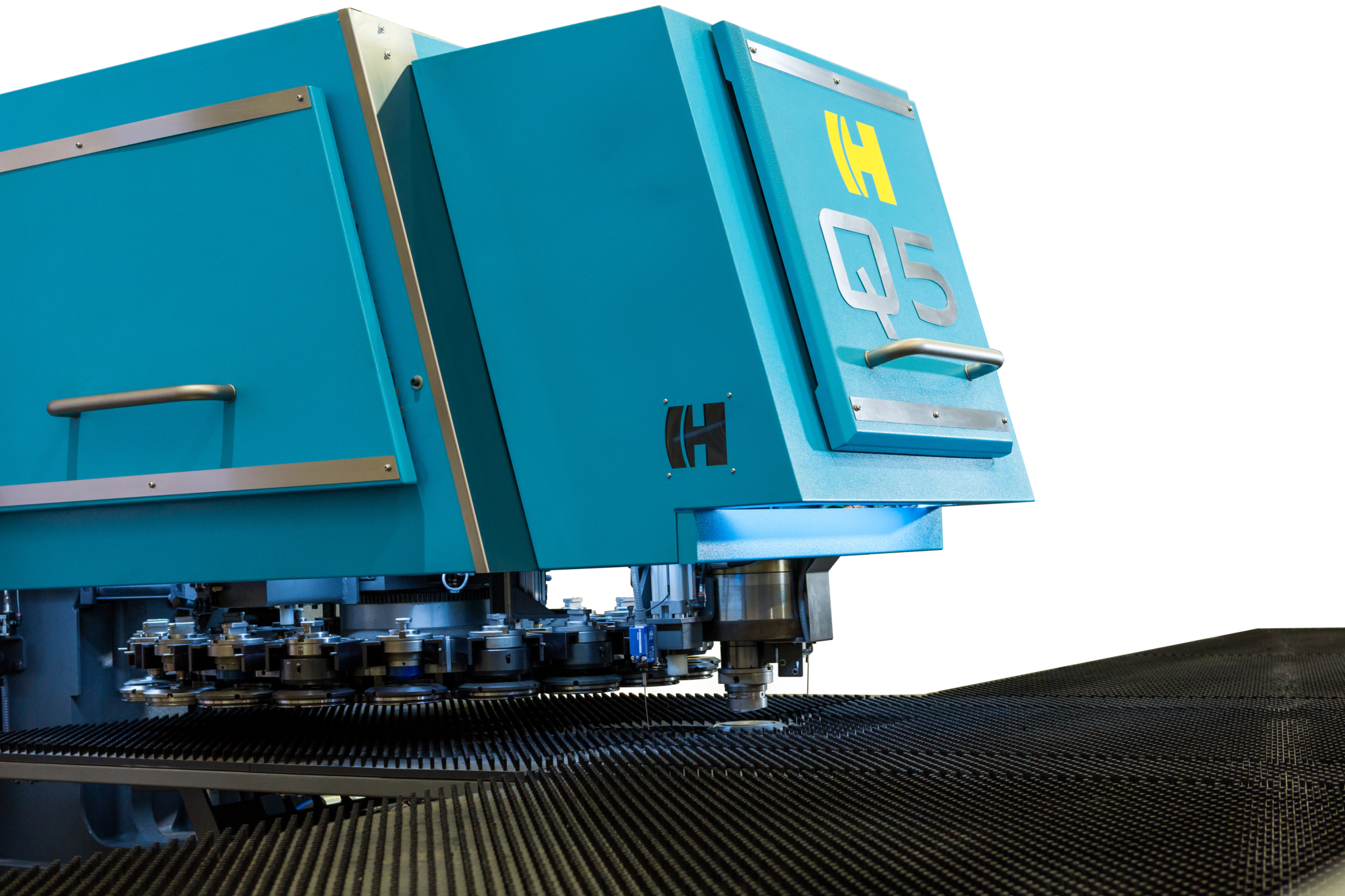

Haco 33 Ton 7-Axis Programmable CNC Turret Punch Press

Inventory # 7413

Model: Q5

Specifications:

Punch Capacity: 33 Tons

Max. Sheet Thickness: 0.256″

Max. Sheet Weight: 440 lbs.

Maximum Hit Rate of Punching Head: 1200 h/min

Stroke X-Axis: 120″ , 4724 ipm , 590 i/s²

Stroke Y-Axis: 60,4″ , 3150 ipm , 393 i/s²

Speed of C-Axis 30° , 60° , 90°: 86 ms , 108 ms , 122 ms

Stroke Z-Axis (Max. Punching Stroke): 1 7/16″

7-Axes programming of:

· X – axis

· Y1 – axis

· Y2 – axis

· Z – axis

· T – axis

· A – axis index punch (C1)

· B – axis index die (C2)

Max. Power Consumption: 34 kW (50 HZ) , 41 kW (60HZ)

Average Power Consumption: 8 kW (50 HZ) , 11 kW (60HZ)

Compressed Air Supply: 87 psi

Voltage: 220 v / 440 v / 3 ph

Standard Features:

Heavy-Duty Frame – total weight +/-14.000 Kg

Problem-free continuous punching-capacity of 30 Tons , max. 6.5 mm sheet thickness

Fully stress-relieved frame by means of heat treatment (up to 600 degrees Celsius, 5 days cooling off cycle)

High geometrical machining accuracy (up to 0.01mm)

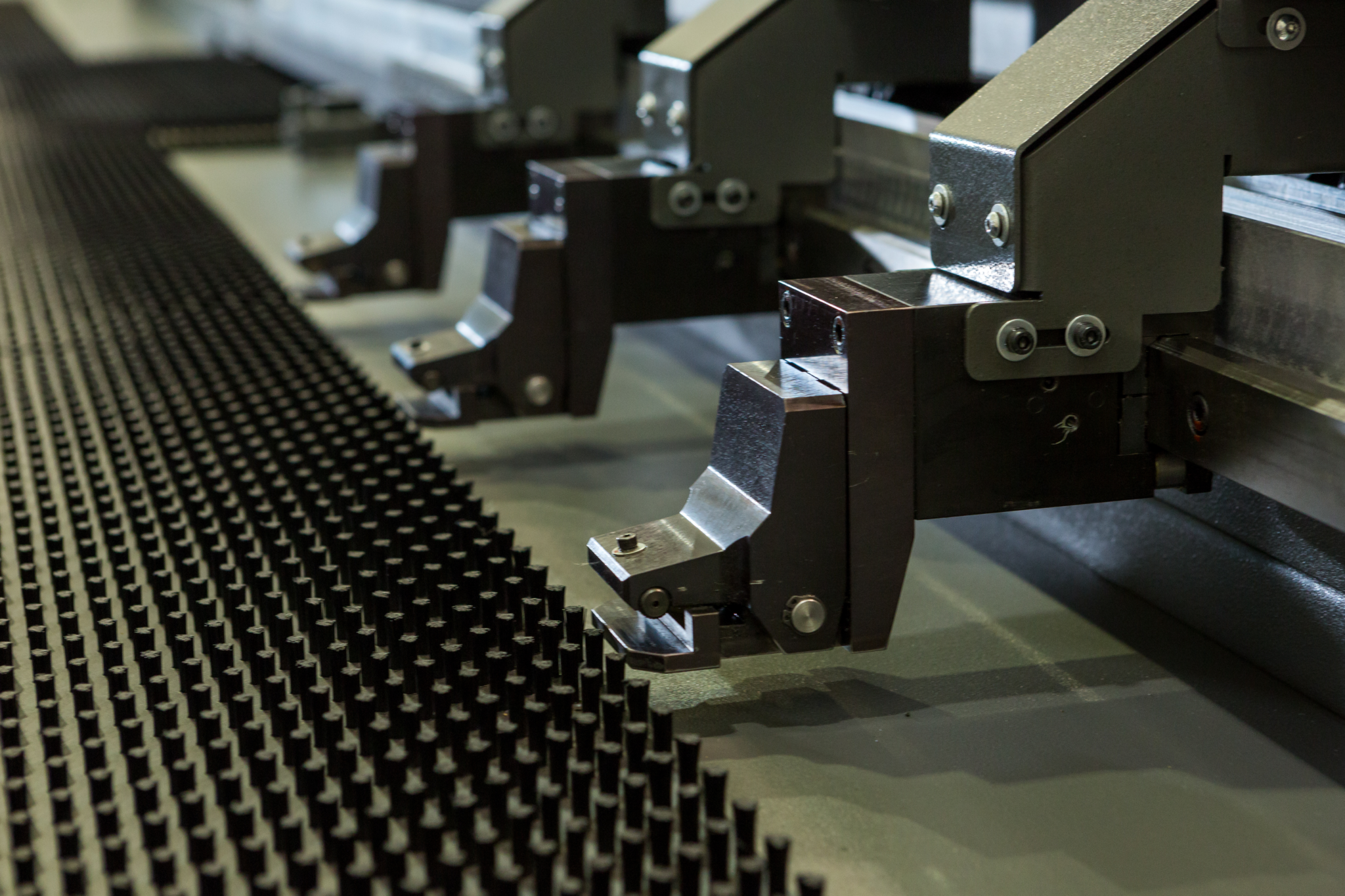

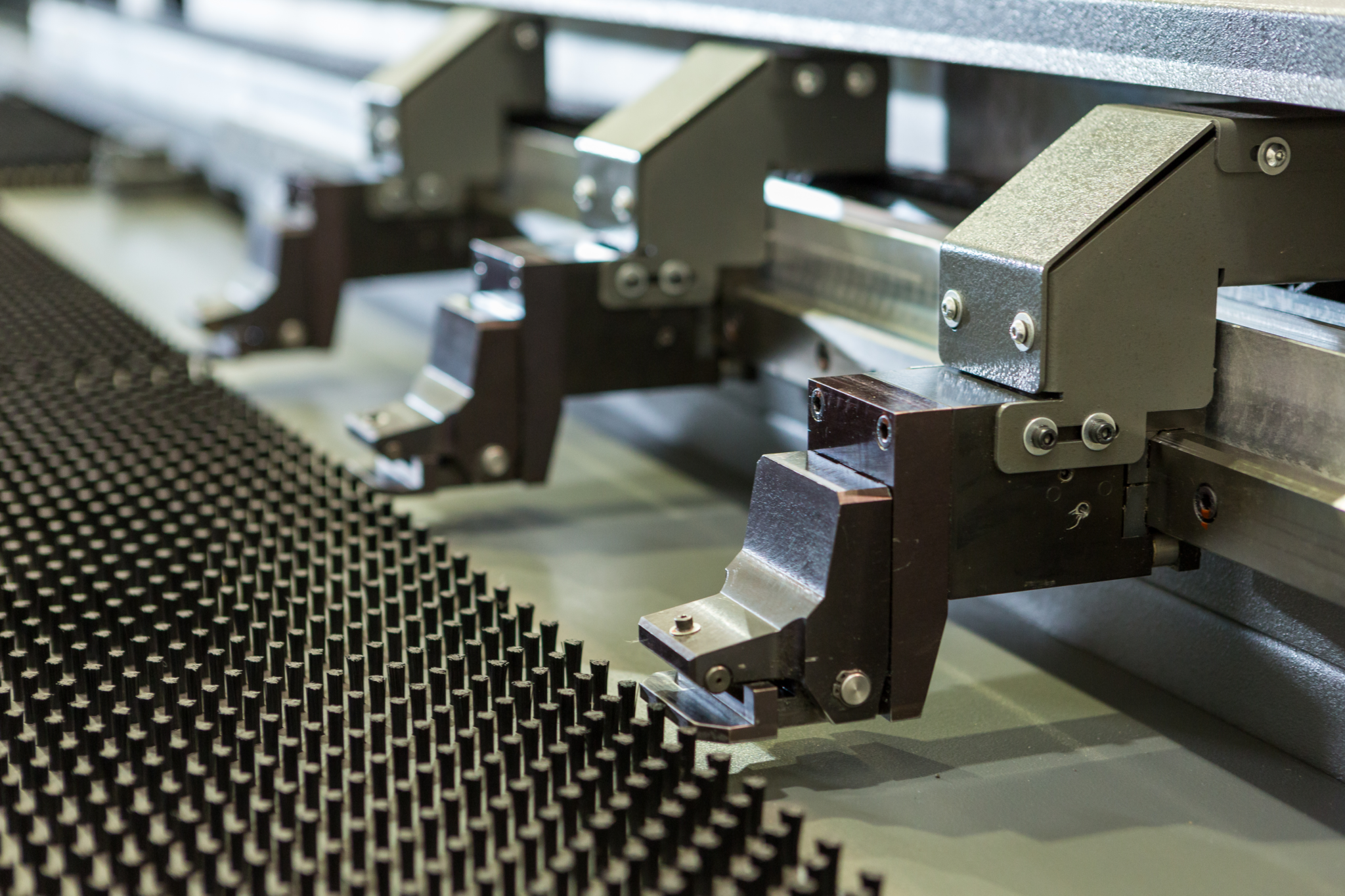

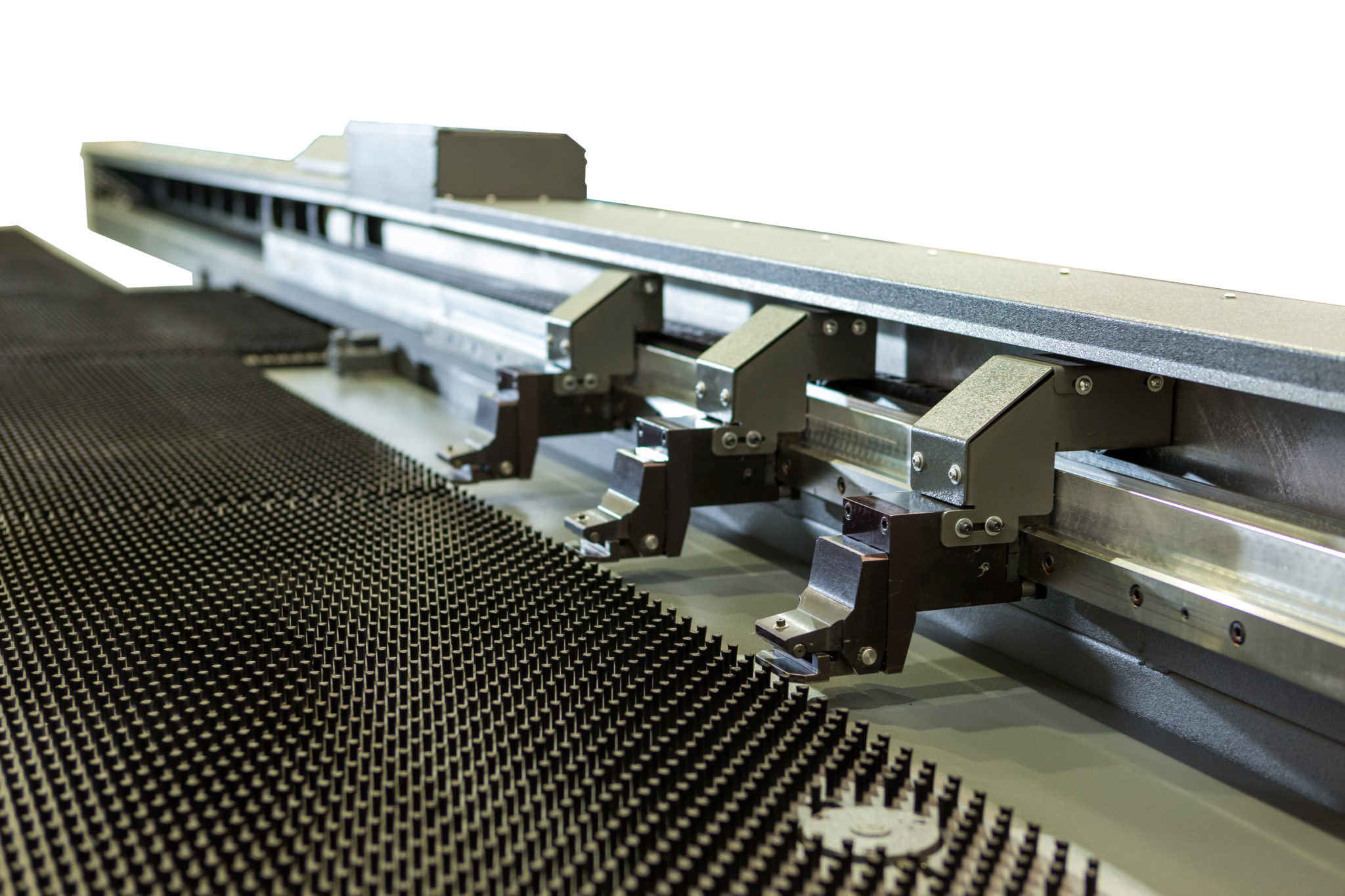

Low Maintenance Punching head situated outside of the tool changer – no turret-wear

Programmable punching depth for optimum cutting quality and minimal tool-wear – no ‘shimming’ after grinding the punching tools.

All tool-stations indexable at high indexing speed ( 250 Rev/min)

Positive clamping – hydraulic quick-clamping of tool holders

Fast and accurate loading of the tools in the turret

Simple construction of the tool holders

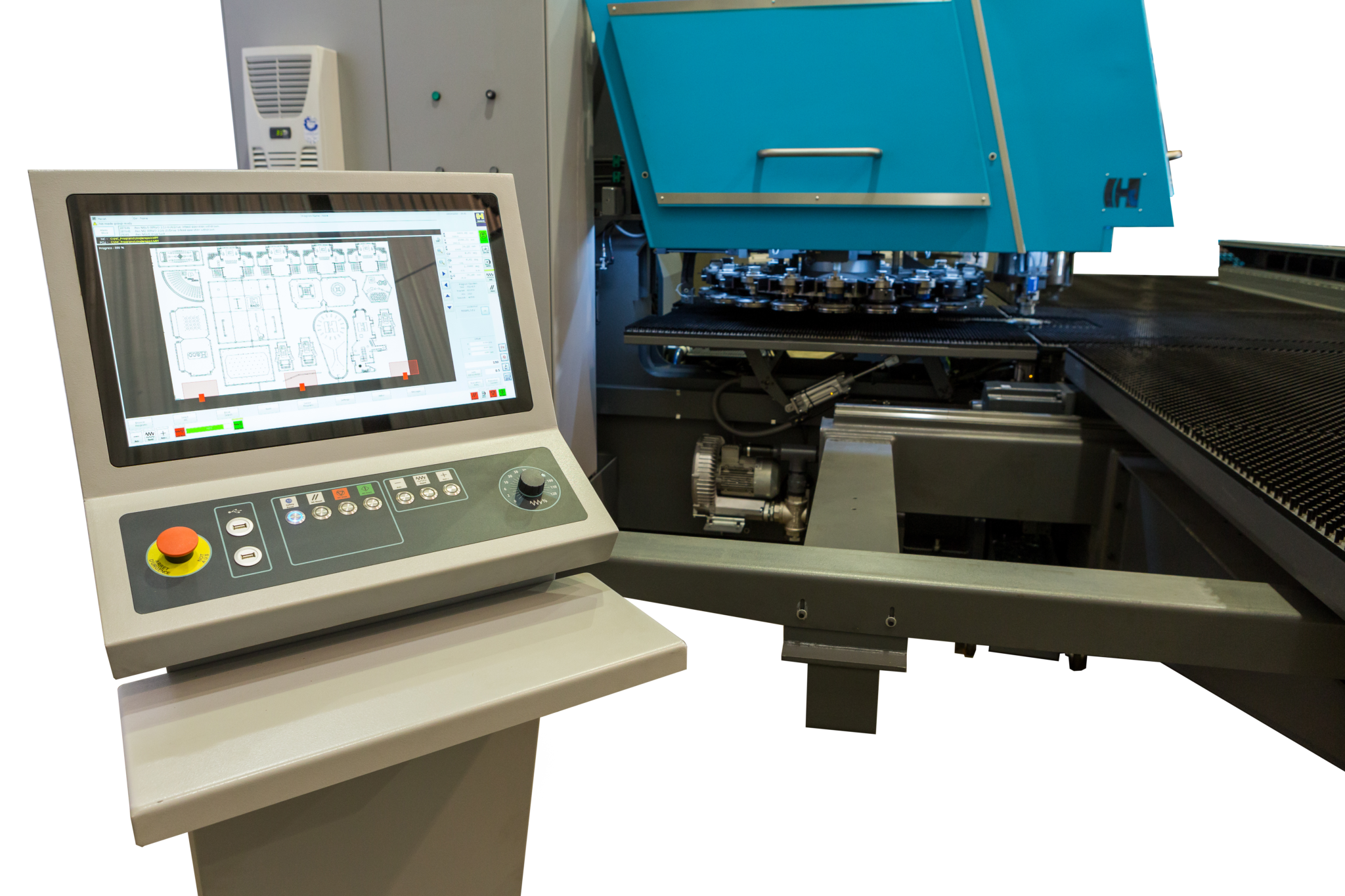

User-friendly Siemens 840D Windows 7 ® based CNC Graphics control

Heavy AC servo motors for X- and Y-axes

Clamps are manual or CNC movable

Interpolation of axis (possible to use wheel tools)

Big part evacuation with integrated conveyor belt and front drop out of parts (option)

Bending capability of 70 mm heights

Equipment Included:

Part Chute with Servo Sliding Gate

Tool-Changer of 20 positions

7-Axes CNC control (X-Y1-Y2-Z-T-C1-C2)

(4) Repositioning cylinders (2 upper and 2 lower cylinders)

(3) Hydraulic CNC-movable sheet-clamps

CE light guard

(8) Vibration dampers

Scrap container

Vacuum system

Energy recuperation system for all axes

Maintenance and programming manuals

HacoSoft Punch CAD/CAM Software:

· Can be used to prepare the whole punching production and generate the CNC programs for the Haco CNC punching machines

· Windows based software

· User friendly 2D CAD functions

· Importing of 2D files : dxf, me10, hpgl, dwg

· Graphical tool library for normal and special tools

· Manual and automatic tool assignment

· Rectangular and true shape nesting

· Manual, automatic and combined nesting

· Common cuts, micro-joints

· Manual and automatic repositioning

· Graphical simulation of the punch process

· Fully integrated in the HacoSoft CAD-CAM System

· Tele service via internet

· Programmable tool functions

· Programmable part chute

· Nest report with time calculation

· Tool linking ( punch, form, tapping)

· Manual and automatic punch sequence

· Adaptive stroke

Mechanical Specifications:

Overall Dimensions: 212.6″ L x 220 1/2″ W x 90″ H

Overall Weight: approx. 30,000 lbs.

Price on Request

FOB Factory